Individual wires, strands, or the cable as a whole may be treated with zinc for improved product features and longevity. The process enhances both the internal properties of the underlying steel and creates a protective exterior layer. Read More…

As leading innovative wire rope manufacturers, Bergen Cable Technology has been providing engineering assistance for well over half a century, helping customers develop cost effective, durable solutions.

JSC, as one of the most diversified wire rope manufacturers, utilizes over 200 production machines to produce top rated wire products in ferrous and nonferrous materials. Industries that JSC serves include electronics, geophysical and communications.

Lexco is an ISO:9001 manufacturer of wire rope, cable, and bungee cord assemblies; and push-pull controls. Our in-house capabilities range from swaging and extrusions to die-casting, proof-loading, and CNC machining. Lexco Cable is proud to serve a diverse set of markets including military, aerospace, OEM, MRO, marine, architectural, and more. Contact us today.

For over 30 years, companies across various markets have relied on Motion Control Technologies to provide high-quality mechanical cable solutions. Our line of products includes commercial cable lanyards, galvanized wire rope cable lanyards, swaged fittings, and more. We strive to build long-lasting relationships with our customers, regardless of your industry. Contact us today and tell us how we...

Aero Assemblies, Incorporated strives to make every effort, as dedicated wire rope manufacturers, to maximize product value throughout the manufacturing process.

More Galvanized Cable Manufacturers

Galvanized steel cables are popular in applications where extreme atmospheric conditions such as temperature and precipitation may otherwise decrease the functionality of wire ropes.

Construction, aeronautics, mining, marine, utilities, communications, automotive, and many other industries frequently use galvanized cable in support and control features. Stainless steel cables are also popular in these applications, though galvanized cables are an economic alternative that boast similar properties and features in less caustic environments.

It is important to take environmental and mechanical stresses into account when selecting the proper galvanized cable. Further considerations include the overall size and diameter, breaking strength, design, and ductility.

Some uses for galvanized cable may also require the use of fittings, fasteners, or other hardware which allow for connectivity and may prevent fraying of the rope. These components may or may not be galvanized dependent upon the requirements of their intended use.

Along with wire rope fittings and other connectors, galvanized cables are composed of three basic parts. Wires are often cold drawn metal filaments of a relatively small diameter. Two or more of these are braided or twisted into a grouping known as a strand which in turn is helically wrapped around a core.

Galvanization is often a post-forming process but can be performed on wires, strands, or completed ropes. The traditional method for galvanizing wire rope is known as hot-dip galvanizing or hot-dipping. Cables, or components, are first cleaned with a light acidic solution before being fed or submerged into a molten zinc bath, heated to around 860°F. The zinc chemically reacts with the iron or steel forming a permanent bond with the substrate. When removed from the bath and subsequently exposed to atmospheric oxygen and carbon dioxide the zinc is cured and forms a protective layer of zinc carbonate.

Electrolytic-galvanizing may also be used for a thinner, more tightly bonded coating made possible by passing an electric current through the zinc compound.

Additional methods include coating the cable with an organic solvent that evaporates while the zinc reacts as well as coating the cable with zinc powder before processing in a rotary oven.

Depending upon the method and specific requirements of a given application, steel cables can be coated with one or more layers of zinc in order to improve strength and corrosion resistance. The thickness of these layers most often ranges between one mil and just over four mils.

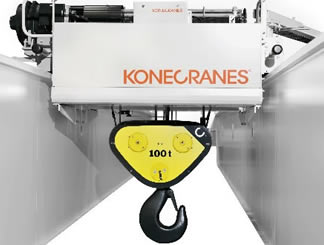

Cranes

Cranes Electric Hoists

Electric Hoists Forklifts

Forklifts Hydraulic Lifts

Hydraulic Lifts Rope

Rope Wire Rope

Wire Rope Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services