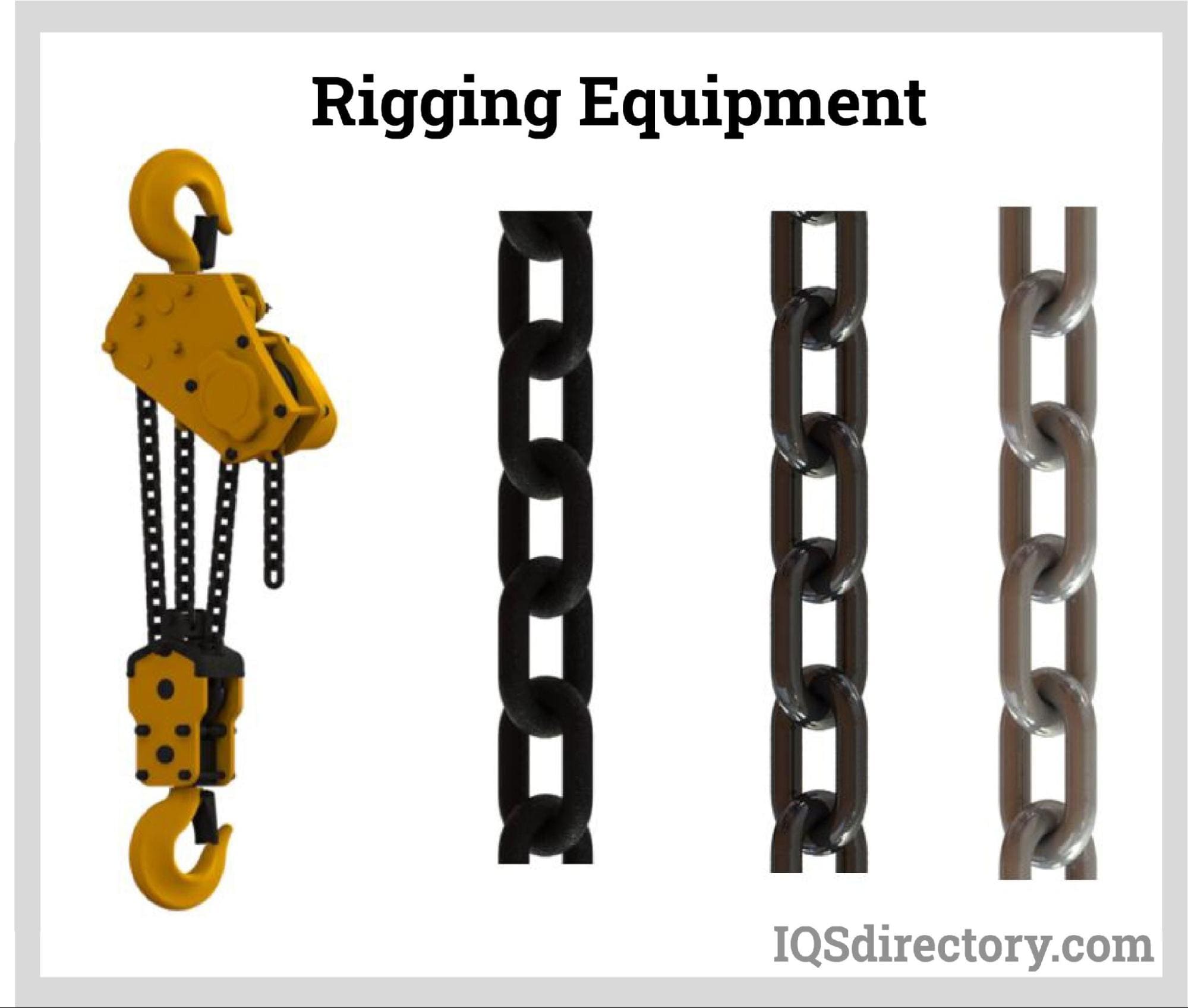

A set of tools called rigging equipment is utilized during a moving operation to hold and distribute big weights. Rigging equipment is used to safely carry goods from one location to another by securing a load to lifting machinery. Businesses frequently use rigging equipment in construction, manufacturing, transportation, and event staging. Read More…

As leading innovative wire rope manufacturers, Bergen Cable Technology has been providing engineering assistance for well over half a century, helping customers develop cost effective, durable solutions.

JSC, as one of the most diversified wire rope manufacturers, utilizes over 200 production machines to produce top rated wire products in ferrous and nonferrous materials. Industries that JSC serves include electronics, geophysical and communications.

Lexco is an ISO:9001 manufacturer of wire rope, cable, and bungee cord assemblies; and push-pull controls. Our in-house capabilities range from swaging and extrusions to die-casting, proof-loading, and CNC machining. Lexco Cable is proud to serve a diverse set of markets including military, aerospace, OEM, MRO, marine, architectural, and more. Contact us today.

For over 30 years, companies across various markets have relied on Motion Control Technologies to provide high-quality mechanical cable solutions. Our line of products includes commercial cable lanyards, galvanized wire rope cable lanyards, swaged fittings, and more. We strive to build long-lasting relationships with our customers, regardless of your industry. Contact us today and tell us how we...

Aero Assemblies, Incorporated strives to make every effort, as dedicated wire rope manufacturers, to maximize product value throughout the manufacturing process.

More Rigging Equipment Manufacturers

Types of Rigging Equipment

Different tool sets with a range of functions are needed for rigging operations. It is essential to understand what they are and how they work to ensure a safe lifting procedure. Below are some examples of the primary rigging equipment categories.

Rigging Hooks & Shackles

Cargo is frequently mounted to a crane with rigging hooks or shackles to connect and move cargo. Heavy loads are kept from slipping in the air due to these items having a firm grip on them. Although they may frequently serve the same purpose, rigging hooks and shackles are designed differently. Rigging hooks normally consist of two components: an integrated spring latch and a loop of steel connected to a chain.

Choker hooks, eye hooks, clevis grabs, and sorting hooks are a few of the most used rigging hooks. Meanwhile, shackles loosely resemble a horseshoe. They secure their connection with a bolt-like device (pin) running through both ends (ears). One end of the pin subsequently features an opening for a tang or split pin to fit through to secure the pin in place.

Wire Ropes

Wire ropes support the load during the lifting process. Its potency and application rely on the following:

- Rope width

- Core material

- Grade of steel wire finish (bright steel, galvanized, stainless steel)

Each rope must be one continuous piece without a knot, per OSHA 1926.251(c)(4). Therefore, it shouldn't have eye splices and endless rope slings at the wire’s ends. Additionally, every rope's eye splice should only contain three complete tucks.

Slings

Slings are flexible, lightweight equipment used with wire ropes to hoist large objects. When moving heavy weights about the site, they offer strength and balance. Slings mainly come in two varieties and are made of synthetic materials:

- Endless sling – takes the form of an unending loop

- Eye-and-eye sling – contains flat, triangular, or twisted ends made of metal, polyester, or nylon

Pulleys & Blocks

Blocks and pulleys work together to lift big objects with minimal force. As a result, they offer sufficient support while lessening the force needed to lift the load. A rigging rope is looped around the pulley and fastened to the item to make the pulley function. While moving the load, the pulley holds the rope. Depending on the type of frame, rope, and sheave size employed, it comes in various sizes. The block also acts as a stabilizing force by supporting the weight being pulled by the rope during the procedure. Snatch, square, and swivel blocks are some of their most popular types.

Eye Bolts

This tool loops cables and serves as an anchor point in rigging applications. Depending on their needs, riggers can choose from various sizes and materials for it. The common varieties of eye bolts are listed below:

- Shouldered bolts are used to load machinery obliquely.

- Straight bolts without shoulders are used to raise things in a vertical system.

- U-bolts, screw eye bolts, and other types of bolts

The following set of factors will determine which eye bolt is best:

- Weight of the load

- Type of sling used

- The angle of loading the object (e.g., angular, vertical)

- The frame material for the bolt (e.g., wood, metal)

Steel Nuts

Steel nuts and eye bolts frequently function together when anchoring a rigging system. As a result, they are available in different sizes and configurations appropriate for various rigging applications. The choice will be based on the load's weight and the thread type (right-hand or left-hand).

Examples of steel nuts include the following:

- Ball ends

- Dome nuts

- Hex nuts

- Lifting eye nuts

- Wingnuts

- Turnbuckles

With the aid of this device, a cable, chain, rope, or another piece of tensioned rigging equipment can be lengthened or tightened. It has two threaded eye bolts, one fastened to each end of a small metal frame. It comes in two varieties: a bottle screw or a stretching screw.

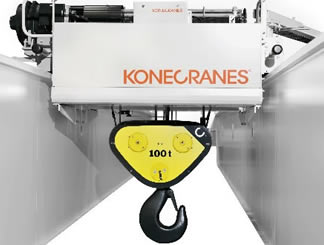

Spreader Bars & Lifting Beams

When lifting, these devices link the target with the crane. They make the lift more manageable by stabilizing the load's weight. The type of load that needs to be supported will determine how they are used. Spreader bars, as their name suggests, work by spreading an object’s weight during lifting. They are the better choice for objects that need to be supported throughout their entire span. Lifting beams, on the other hand, absorb a load's weight more centrally. Lifting beams offer less stability in their function but may require less clearance space to operate.

Considerations When Selecting Rigging Equipment

The following set of factors must be taken into account when choosing the appropriate kind of rigging equipment to use:

- The item to be moved and its size

- The item’s weight

- The hook opening's dimensions

- A hoist’s incline and attachment sites

Choosing the Correct Rigging Equipment Supplier

To make sure you have the most constructive outcome when purchasing Rigging Equipment from a Rigging Equipment Supplier, it is important to compare at least 4 or 5 Manufacturers using our Rigging Equipment directory. Each Rigging Equipment Supplier has a business profile page that highlights their areas of experience and capabilities and a contact form to directly communicate with the manufacturer for more information or request a quote. Review each Rigging Equipment company website using our patented website previewer to get an idea of what each company specializes in, and then use our simple RFQ form to contact multiple Rigging Equipment businesses with the same quote.

Cranes

Cranes Electric Hoists

Electric Hoists Forklifts

Forklifts Hydraulic Lifts

Hydraulic Lifts Rope

Rope Wire Rope

Wire Rope Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services