The worlds of aerospace and aircraft have a wide assortment of components that seem inconsequential when compared to the grander scheme of building a fuselage or proper wing design. Many of these hidden benefits are tucked away in the dark or buried in a control panel. One item, in particular, that has been a major addition to aircraft operations, is the safety cable that has been designed to keep fasteners and connectors in place. Read More...

Bergen Cable Technology, Inc.

As leading innovative safety cable manufacturers, Bergen Cable Technology has been providing engineering assistance for well over half a century, helping customers develop cost effective, durable solutions. Bergen will meet consumer needs for reliable fittings & provide prototypes & short runs to ensure top-quality. Let Bergen’s unmatched dedication to quality bring you the service you deserve.

Fairfield, NJ |

800-237-4369

Request for Quote

More Safety Cable Manufacturers

Safety cables function much like a safety line for a climber. For many years, aircraft designers realized that the vibrations from the operation of an airplane caused bolts and other forms of connectors and fasteners to loosen. In an attempt to overcome the problem, they joined connectors with wires that were tightly stretched between fasteners to prevent movement. The process worked, on the surface, but had several issues.

Regardless of the gauge of wire used, it broke from the vibration of the aircraft and had to be constantly repaired or replaced. To be proactive, the wires were constantly checked for possible problems, which caused delays and slowed operations. Also, wires had the added danger of snapping or disconnecting.

In the mid-80’s, aircraft manufacturers realized they had to devise a more secure method to keep fasteners from failing. After experimenting with various designs, they developed the concept of the safety cable, which is made from several strands of tightly wound wire. The initial concept fulfilled several of the criteria that producers required, which included excellent tension control, safety, and little need for repair or monitoring.

The introduction of safety cables has led to peak performance of aircraft and the avoidance of delays due to a broken wire or the need for wire replacement. Today, safety cables are an essential part of aircraft production and safety.

Much like their wire counterparts, safety cables are designed to create tension between fasteners to prevent them from loosening during flight operations. The multiple strands take the strength of a single wire and increase it with the strength of several. It is much like having multiple hands doing a job instead of one.

The safety cable is another of those small pieces that serve an important part in keeping aircraft safe. Their introduction has offered extra insurance of efficient and smooth flight operations.

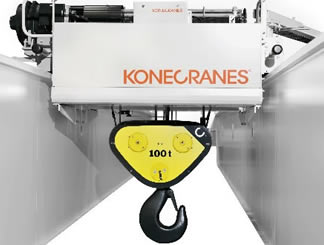

Cranes

Cranes Electric Hoists

Electric Hoists Forklifts

Forklifts Hydraulic Lifts

Hydraulic Lifts Rope

Rope Wire Rope

Wire Rope Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services