Wire rope assemblies are crucial in many industrial and commercial applications because they provide the strength and endurance needed to sustain big loads and safeguard priceless goods. These ropes are created by twisting numerous separate wires to create a sturdy cord-like structure. As a result, the rope’s strength and elasticity might change depending on the wire count, twist pattern, and core material. Read More…

As leading innovative wire rope manufacturers, Bergen Cable Technology has been providing engineering assistance for well over half a century, helping customers develop cost effective, durable solutions.

JSC, as one of the most diversified wire rope manufacturers, utilizes over 200 production machines to produce top rated wire products in ferrous and nonferrous materials. Industries that JSC serves include electronics, geophysical and communications.

Lexco is an ISO:9001 manufacturer of wire rope, cable, and bungee cord assemblies; and push-pull controls. Our in-house capabilities range from swaging and extrusions to die-casting, proof-loading, and CNC machining. Lexco Cable is proud to serve a diverse set of markets including military, aerospace, OEM, MRO, marine, architectural, and more. Contact us today.

For over 30 years, companies across various markets have relied on Motion Control Technologies to provide high-quality mechanical cable solutions. Our line of products includes commercial cable lanyards, galvanized wire rope cable lanyards, swaged fittings, and more. We strive to build long-lasting relationships with our customers, regardless of your industry. Contact us today and tell us how we...

Aero Assemblies, Incorporated strives to make every effort, as dedicated wire rope manufacturers, to maximize product value throughout the manufacturing process.

More Wire Rope Assembly Manufacturers

From small-diameter ropes used for light applications to big, heavy-duty ropes capable of bearing many tons of weight, wire ropes are available in various sizes. They can also be built from various materials, such as steel, stainless steel, or fiber-reinforced composites to fit particular uses and situations. The ropes can also be coated or treated to extend their longevity and resist corrosion.

Wire rope assemblies are essential to maintaining the stability and safety of numerous commercial and industrial operations. They are a vital tool in many industries due to their strength, durability, and versatility, which offer a dependable alternative for lifting and securing heavy objects.

Types of Wire Rope Assemblies

There are different varieties of wire rope assemblies; each one created for certain situations and applications. The most typical varieties include:

Bright Wire Rope: is the most fundamental variety of wire rope and is distinguished by its smooth surface, which is uncoated or treated in any other way. It is frequently utilized in low-friction applications, including control cables, hoisting ropes, and winch lines.

Galvanized Wire Rope: has been galvanized and has a layer of zinc coating on it to prevent corrosion. It is frequently used for hoisting and securing freight and in maritime and offshore applications. This kind of wire rope is made of corrosion-resistant stainless steel, making it perfect for usage in challenging conditions like maritime and offshore applications, the food processing industry, and the medical sector.

Wire Rope with a Fiber Core: This kind of wire rope has a fiber core made of manila or sisal, which adds strength and helps the rope keep its shape. Fiber core wire ropes are frequently employed in demanding situations like towing and crane hoisting.

Coated Wire Rope: is coated with plastic to offer additional defense against corrosion and resistance to wear and abrasion. It is frequently employed in situations requiring extra security, such as ski lift ropes and amusement park attractions.

Compacted Wire Rope: Wire rope that has been tightly compacted and has a higher wire count is known as a "compacted wire rope." It has more strength and durability than a traditional wire rope. It is frequently utilized in high-load applications, like heavy-duty cranes and offshore oil rigs.

These are only a few of the various types of wire rope assemblies available; the type utilized will be determined by the application's unique needs, such as load capacity, environment, and budget.

Applications of Wire Rope Assemblies

Wire rope assemblies have a wide range of applications, due to their strength, durability, and versatility. Construction, shipping, mining, oil and gas, and other industries use wire ropes. They are frequently used in construction as hoisting lines to raise large objects and supplies or as safety lines to secure personnel at high altitudes. Some of the most common applications include:

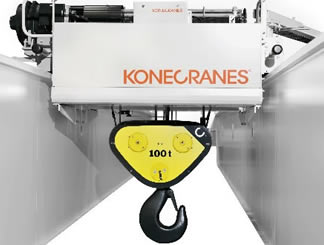

Lifting and Hoisting: Wire ropes are widely used for lifting and hoisting heavy loads, such as construction materials, machinery, and containers. They are commonly used in cranes, elevators, and hoists in industrial and commercial applications.

Towing and Pulling: Wire ropes are also used for towing and pulling heavy loads, such as ships, vehicles, and construction equipment. They provide a strong and reliable connection between the towing vehicle and the load, allowing for safe and efficient transport.

Mooring: In the shipping and maritime industries, wire ropes are used for mooring ships, securing them in place while at port or anchor. Wire ropes also secure cargo while it is transported.

Structural Support: Wire ropes can also be used for structural support for suspension bridges and aerial tramways. They provide a strong and flexible connection between support points, allowing for safe and stable construction.

Mining: In the mining industry, wire ropes are used for hoisting miners and equipment and transporting minerals from deep underground. They offer a secure and effective way to move people and materials around the mine.

Entertainment: Wire ropes are also used in entertainment applications, such as theme park rides and ziplines, providing riders a secure and exciting experience.

Agricultural: In agriculture, wire ropes are used for various applications, including securing silage covers, pulling carts, and supporting crop covers.

These are but a few of the numerous uses for wire rope assemblies. The particular kind chosen will depend on the application’s needs, such as weight capacity, environment, and budget. However, with their strength, durability, and versatility, wire ropes play a critical role in many industrial and commercial operations.

Benefits of Wire Rope Assemblies

Wire rope assemblies offer a range of benefits, making them an essential component in many industrial and commercial applications. Some of the key benefits include:

Strength and Durability: Wire ropes are perfect for heavy-duty applications because of their renown for strength and toughness. They can support large loads and resist damage from wear and tear, providing a long-lasting solution for lifting and securing heavy loads.

Flexibility: Wire ropes have a high degree of flexibility, allowing them to bend to support a load. This ability to bend makes them ideal for use in applications requiring a flexible connection, such as hoisting and towing.

Versatility: Wire ropes can be made from various materials, such as steel, stainless steel, and fiber-reinforced composites, to suit specific environments and applications. Wire ropes can also be treated or coated to improve their lifespan and performance while providing a versatile solution for various applications.

Safety: Wire ropes play a critical role in ensuring the safety of commercial and industrial operations. They provide a secure connection between loads and support points, reducing the risk of accidents and injury.

Cost-Effective: Wire ropes are cost-effective compared to other materials, such as chains and cables. In addition, they offer a high return on investment, as they can support heavy loads and resist wear and tear, providing a reliable solution for many years.

Efficient: Wire ropes operate efficiently, as they allow for quick and easy attachment and detachment of loads, reducing downtime and increasing productivity.

Choosing the Right Wire Rope Assemblies Company

To make sure you have the most productive outcome when purchasing Wire Rope Assemblies from a Wire Rope Assemblies Supplier, it is important to compare at least 4 Companies using our Wire Rope Assemblies directory. Each Wire Rope Assemblies Company has a business profile page that highlights their areas of experience and capabilities and a contact form to directly communicate with the manufacturer for more information or request a quote. Review each Wire Rope Assemblies business website using our patented website previewer to get an idea of what each business specializes in, and then use our simple RFQ form to contact multiple Wire Rope Assemblies businesses with the same message.

Cranes

Cranes Electric Hoists

Electric Hoists Forklifts

Forklifts Hydraulic Lifts

Hydraulic Lifts Rope

Rope Wire Rope

Wire Rope Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services