While the terms wire rope and cable are often used interchangeably, cables are typically designated as smaller diameter wire ropes, specifically wire ropes with a diameter less than 3/8 inch. Therefore, wire rope cable assemblies are typically utilized for lighter duty applications. Read More…

As leading innovative wire rope manufacturers, Bergen Cable Technology has been providing engineering assistance for well over half a century, helping customers develop cost effective, durable solutions.

Lexco is an ISO:9001 manufacturer of wire rope, cable, and bungee cord assemblies; and push-pull controls. Our in-house capabilities range from swaging and extrusions to die-casting, proof-loading, and CNC machining. Lexco Cable is proud to serve a diverse set of markets including military, aerospace, OEM, MRO, marine, architectural, and more. Contact us today.

At Kennedy Wire Rope & Sling Company, we take pride in being a trusted source for high-performance wire ropes that keep industries moving safely and efficiently. We engineer and supply wire rope solutions that meet the rigorous demands of lifting, rigging, and load-handling applications across construction, marine, energy, and industrial markets.

Aero Assemblies, Incorporated strives to make every effort, as dedicated wire rope manufacturers, to maximize product value throughout the manufacturing process.

At Zauderer Associates, Inc., we specialize in providing high-quality wire rope solutions designed for durability, safety, and reliability across diverse industries. With extensive experience and technical expertise, we offer a comprehensive range of wire ropes tailored to meet rigorous performance requirements.

More Wire Rope Cable Assembly Manufacturers

While cable assemblies may not offer the same brute strength as heavy duty wire ropes, they are utilized in a very diverse range of industries. The aerospace, automotive, electronic, agriculture, medical, security, and many other industries make extensive use of wire rope cable assemblies in a multitude of applications. This diversity is achieved through the great depth of features and customization available to manufacturers.

One of the most important and defining features of any cable assembly is its basic construction. Cable assemblies are manufactured by twisting or bonding small wires into bundles and twisting or bonding these bundles into a larger cable.

A very common cable construction is comprised of seven bundles of nineteen wires, called 7x19. Cables also come in 1x19, 7x7, 6x19, 6x25, 8x19, 8x25, and many other construction configurations.

The type of construction used has the largest effect on the strength of the cable. Wire rope cable assemblies can be designed with breaking strengths greater than 14,000 pounds.

Depending on the requirements of a given application, cables can be further customized based on flexibility, environmental factors, functionality, and cost.

Larger diameter cables are generally less flexible than smaller diameter cables, so this is another important factor to consider when deciding on the construction of the cable assembly.

In terms of cable composition, steel is by far the most commonly used cable material due to its strength, but stainless steel and galvanized steel also provide excellent corrosion and abrasion resistance for particularly harsh environments.

End fittings and terminals are also available to create cables with more specialized uses. Cable assemblies can be fitted with knobs, stops, threaded studs, loops, sleeves, thimbles, and many other terminals to alter functionality.

Of course, greater customization, as well as larger and stronger cables, will increase the prices of these cables, so it is also important to determine which features are truly essential for your applications to stay within your budget.

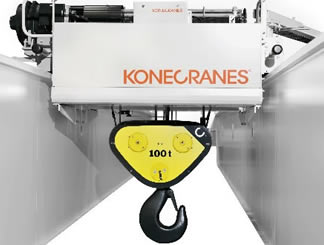

Cranes

Cranes Electric Hoists

Electric Hoists Forklifts

Forklifts Hydraulic Lifts

Hydraulic Lifts Rope

Rope Wire Rope

Wire Rope Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services