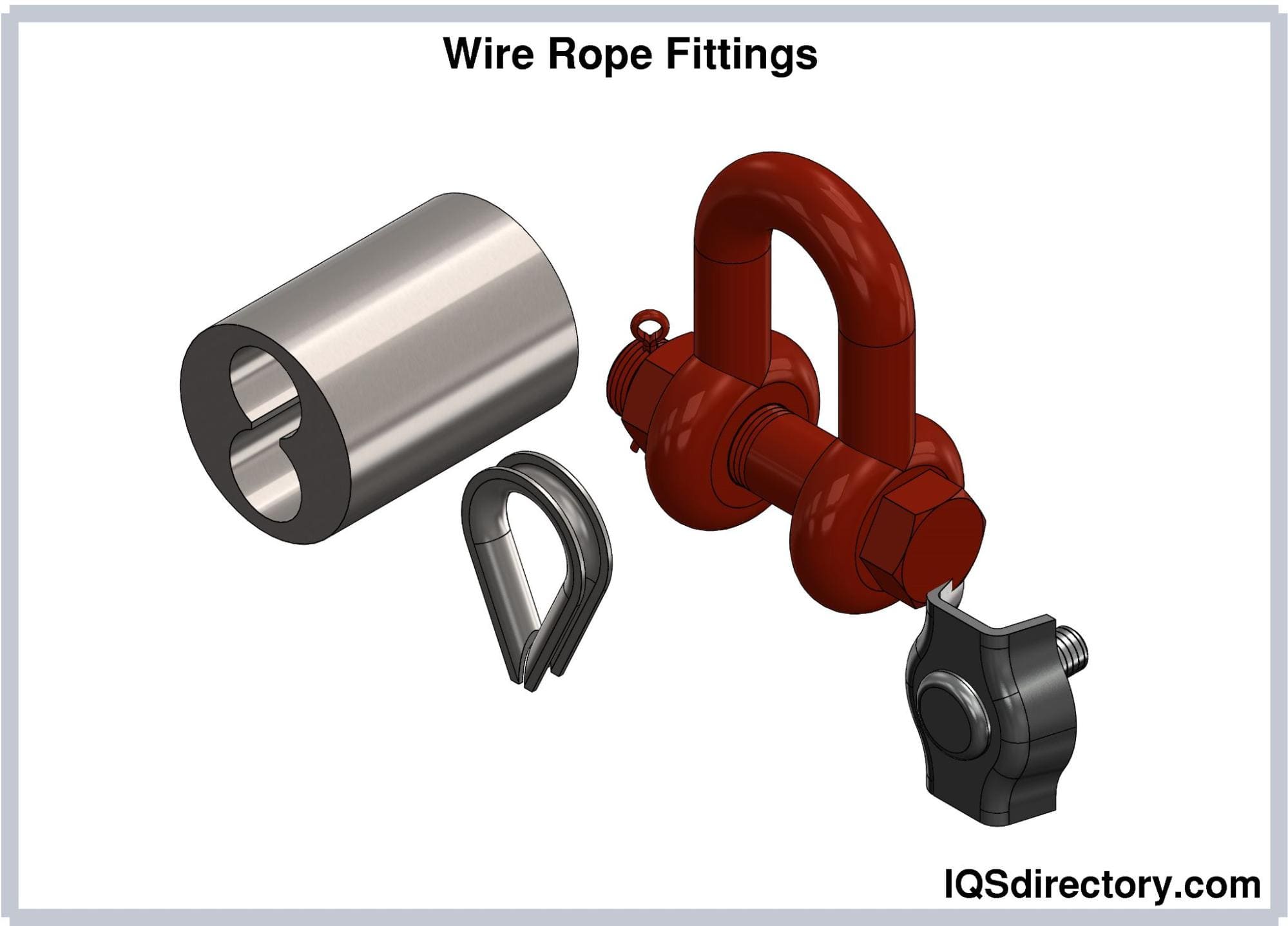

The parts known as wire rope fittings hold the wires’ ends together so they may join to something else. Numerous fitting types are offered in a range of sizes and finishes. Swaged terminations, wire rope clips, poured sockets, and swageless fittings are some of the most popular varieties. These fittings perform various functions in addition to holding the ends of wire rope. For instance, wire rope fittings are used with manual and electric winches to safely rig heavy machinery and cargo. Read More…

As leading innovative wire rope manufacturers, Bergen Cable Technology has been providing engineering assistance for well over half a century, helping customers develop cost effective, durable solutions.

JSC, as one of the most diversified wire rope manufacturers, utilizes over 200 production machines to produce top rated wire products in ferrous and nonferrous materials. Industries that JSC serves include electronics, geophysical and communications.

Lexco is an ISO:9001 manufacturer of wire rope, cable, and bungee cord assemblies; and push-pull controls. Our in-house capabilities range from swaging and extrusions to die-casting, proof-loading, and CNC machining. Lexco Cable is proud to serve a diverse set of markets including military, aerospace, OEM, MRO, marine, architectural, and more. Contact us today.

For over 30 years, companies across various markets have relied on Motion Control Technologies to provide high-quality mechanical cable solutions. Our line of products includes commercial cable lanyards, galvanized wire rope cable lanyards, swaged fittings, and more. We strive to build long-lasting relationships with our customers, regardless of your industry. Contact us today and tell us how we...

Aero Assemblies, Incorporated strives to make every effort, as dedicated wire rope manufacturers, to maximize product value throughout the manufacturing process.

More Wire Rope Fitting Manufacturers

In these situations, a wire rope clip made of nuts and a U-shaped bolt with a grooved base will securely retain the wire rope. In addition, the cable is shielded from wear and damage by a wire sleeve utilized with the rope clip. Machine activities in various conditions need the assembly of wire rope ends with the appropriate fitting.

Wire rope and control cable fittings include clips, sleeves, stud ends, eyes, forks, and other hardware used to construct mechanical cable assemblies. Wire rope and control cable fittings are used for motion control and machine automation applications. A cable clip attaches network cables to wooden joints and studs. A cable clip avoids puncturing the protective jacket outside and the short-circuiting transmission wires inside the cable. In addition, a cable clip also prevents the wires from deforming and destroying the cross-sectional area, which affects the transmission characteristics. A hammer should be carefully used while doing a cable fitting. A hammer can easily break and destroy the cable when striking at the cable. Moreover, a cable fitting can be done using cable hangers and trays.

A wire rope clip is used to hold rope wires, which provides tight and proper holding power to the rope wire. A wire rope clip consists of a U-shaped bolt with a grooved base and nuts to hold the rope wire tightly. A wire rope fitting consists of chain and anchor shackles, swivel hooks, and plate hooks. Wire rope ends are assembled using a wire rope fitting. Assembling wire rope ends is necessary for carrying out machinery operations. A wire sleeve is used with a wire rope clip to prevent wear, tear, and damage to the cable. Other wire rope and control cable fittings are commonly available.

Types of Wire Rope Fittings and Accessories

Wire rope fittings are available in a variety of styles, including:

Clevis (Fork, Jaw) Fittings:

These socket fittings, manufactured in various finishes, including stainless steel, are used in various applications, from heavy-duty machinery to sailboat rigging. They are offered in forged or machined series.

Marine Eye Fittings:

Marine eye fittings are categorized by the oval eye, towing eye, forged, and machined series. These fittings are available in a range of finishes, including stainless steel, self-colored steel, steel with a zinc coating, and galvanized steel. These coatings are essential to prevent corrosion from saltwater since these fittings are generally used in marine applications.

Drum Sockets and Coupling Fittings:

These sockets are available in various metals, such as zinc-plated steel, galvanized steel, and self-colored steel. Drum sockets are used during the installation of plugs. Couplings are used to link two wire rope ends together.

Stud Fittings:

Coarse and fine-threaded stud socket fittings are produced in stainless steel, steel with a zinc coating, steel that has been galvanized, and steel that has a natural color. These fittings can be used alone or with a turnbuckle to tension the wire rope. Stud fittings are used to prevent the ends of pipes from turning or loosening to prevent fluid leakage.

Turnbuckles:

These fittings have stud fittings that tighten or loosen wire rope by attaching them to the rope. Turnbuckles are used to reduce slack and adjust the tension in a cable or wire rope.

Swivel Hooks, Swivel Eye Hooks, and Grab Hook Fittings:

Although designed with distinct variations, these items are used to connect two lines together while allowing each line to rotate independently.

Lifeline Fittings:

Most lifeline fittings are used on military ships. They are available in various styles, including closed-body turnbuckles with sister hooks and clevis fittings with and without sister hooks. Lifeline fittings are used primarily on ships of various sizes to connect rope sections along their perimeter. As the name indicates, their purpose is to prevent people (along with various objects) from falling overboard.

Assembly Kits:

For all wire rope sizes, assembly kits are available to simplify the assembly fittings. These kits come with plug drivers and assembly blocks that can be used to unlay the wire rope strands.

Replacement Sleeves and Wire Rope Plugs:

Along with a comprehensive selection of wire rope plugs made to operate with various wire rope constructions, replacement sleeves are also available.

Wire Rope Fittings Shapes and Sizes

Fittings for wire rope and control cables come in various sizes and shapes. A cable clip should have a diameter of 6.35 mm or less than 0.25 inches. This cable complies with the TIA/EIA 568-B.2 standard for cable diameter. A cable hanger should be used for a cable fitting. A product identification number should be on each wire clip (PIC). The wire clip's code is helpful for material tracking. Galvanizing is necessary to protect a wire rope clip against rust and corrosion. A wire rope clip should also feature a red U-BOLT for quick and simple identification.

Wire sleeves are a crucial component of control cable and wire rope fittings. There are several sizes of wire sleeves. The number of strands handled by each rope is the basis for categorizing a wire rope end fitting. Most industrial criteria are met by the design and production of wire rope and control cable fittings.

Applications of Wire Rope Fittings

There are numerous applications for wire rope and control cable fittings. The automotive, power, and transportation industries are a few examples. Therefore, the American Iron and Steel Institute (AISI), the Telecommunications Industry Association (TIA), and the Electronic Industries Association (EIA) standards should be followed when designing wire rope and control cable fittings. Many different industries employ wire rope fittings for both commercial and industrial uses. A fitting is necessary whenever a wire rope is used to keep its ends safe and attach it to other machinery or components. The following industries typically use wire rope fittings:

- Architecture and Engineering

- Automotive

- Construction

- Energy and Power

- Military

- Transportation

Many heavy-duty applications that entail lifting, hoisting, supporting, or securing machinery and other components use wire rope fittings. They are also utilized in various non-industrial applications, including rigging sailboats, walkways, bridges, and ship railings, as well as with certain sports equipment.

Choosing the Correct Wire Rope Fittings Company

To make sure you have the most productive outcome when purchasing Wire Rope Fittings from a Wire Rope Fittings Supplier, it is important to compare at least 4 Suppliers using our list of Wire Rope Fittings companies. Each Wire Rope Fittings Manufacturer has a business profile page that highlights their areas of experience and capabilities and a contact form to directly communicate with the manufacturer for more information or request a quote. Review each Wire Rope Fittings business website using our proprietary website previewer to get an idea of what each business specializes in, and then use our simple RFQ form to contact multiple Wire Rope Fittings companies with the same quote.

Cranes

Cranes Electric Hoists

Electric Hoists Forklifts

Forklifts Hydraulic Lifts

Hydraulic Lifts Rope

Rope Wire Rope

Wire Rope Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services