Steel wires are twisted together to form a helix structure to create the cables known as wire rope lanyards. Cranes, hoists, lifts, and elevators are just a few of the industrial and commercial applications where they are frequently utilized. Because of their strength, adaptability, and longevity, wire rope lanyards are a popular choice for numerous applications involving heavy weights and high levels of stress. Read More…

As leading innovative wire rope manufacturers, Bergen Cable Technology has been providing engineering assistance for well over half a century, helping customers develop cost effective, durable solutions.

JSC, as one of the most diversified wire rope manufacturers, utilizes over 200 production machines to produce top rated wire products in ferrous and nonferrous materials. Industries that JSC serves include electronics, geophysical and communications.

Lexco is an ISO:9001 manufacturer of wire rope, cable, and bungee cord assemblies; and push-pull controls. Our in-house capabilities range from swaging and extrusions to die-casting, proof-loading, and CNC machining. Lexco Cable is proud to serve a diverse set of markets including military, aerospace, OEM, MRO, marine, architectural, and more. Contact us today.

Continental Cable Co. fabricates cable assemblies, wire rope assemblies, aircraft cables and plastic coated cables. We offer both domestic and imported cables and are capable of producing cable diameters through 1-inch in various constructions and materials. Small quantity orders are welcome.

Aero Assemblies, Incorporated strives to make every effort, as dedicated wire rope manufacturers, to maximize product value throughout the manufacturing process.

At Zauderer Associates, Inc., we specialize in providing high-quality wire rope solutions designed for durability, safety, and reliability across diverse industries. With extensive experience and technical expertise, we offer a comprehensive range of wire ropes tailored to meet rigorous performance requirements.

More Wire Rope Lanyard Manufacturers

Lanyards are coated wire ropes covered in plastic or another substance for increased protection and better grip. The best type of wire rope lanyard will be chosen depending on the application and specifications, including weight capacity, environmental factors, and convenience of use.

The core, the strands, and the individual wires are the three parts of a wire rope lanyard. The strands are composed of separate wires twisted together to form a bigger structure, whereas the core gives the rope its overall shape and structure. The wire rope and individual wires are finally twisted together to create the finished product.

One of a lanyard’s key advantages is its excellent strength-to-weight ratio. This strength-to-weight ratio makes them perfect for applications involving heavy loads and high levels of stress since they can support these loads with less material, which lowers the system's overall weight.

Lanyards made of wire rope are renowned for being strong and long-lasting. Steel wire is an extremely strong and resilient material, and the wire rope's helix structure adds strength and stability. Because they can handle enormous loads and high levels of strain for an extended period, wire rope lanyards are the best option for applications involving these conditions.

Lanyards made of wire rope are available in various styles, dimensions, and features to suit the demands of various applications. In addition, they are strong and long-lasting since they are built of premium materials like galvanized steel and stainless steel.

The adaptability of wire rope lanyards is another benefit. They can be produced in various shapes and sizes to fit a range of applications, and they are easily customizable to satisfy particular needs. Additionally, they come in various coatings and finishes that increase their lifetime and offer additional protection.

Galvanized, PVC, and polypropylene are just a few of the coatings and finishes available for wire rope lanyards. The rope is given additional protection from corrosion and abrasion by these coatings, extending its lifespan and assisting in maintaining its performance over time.

From small-diameter ropes used in fishing lines to big-diameter ropes used in heavy lifting applications, wire rope lanyards are offered in various diameters. In addition, they come in different constructions, including regular lay, Lang lay, and Warrington lay. Each design has special qualities that make it suitable for various uses.

The most popular wire rope lanyard is known as regular lay construction, and its regularly spaced wires distinguish it. This structure offers a balance of flexibility and strength for applications like crane cables, where a mix of both is required.

On the other hand, the more tightly coiled wires of Lang lay construction give it its distinctive appearance. In applications requiring high tensile strength, such as hoists and lifting cables, this structure results in a rope with a higher degree of tensile strength.

The construction method used in Warrington is further distinguished by its alternating left and right twists. This design gives the rope greater flexibility, making it better suitable for uses that call for bending and twisting, like in elevator cables.

Types of Wire Rope Lanyards

Various varieties of wire rope lanyards are available to satisfy the requirements of various applications. Typical types include:

Lanyards constructed of galvanized wire rope are rust-resistant and made of galvanized steel, making them perfect for outdoor use.

Lanyards constructed of stainless steel wire rope are of the highest quality, adding to their longevity and resistance to corrosion.

Lanyards made of wire rope come in two different configurations, 7x7 and 7x19, with 7x7 being more flexible and 7x19 being more rigid.

The terminal end of swaged wire rope lanyards has been swaged (crimped) to facilitate attachment to a hook or other connector.

Applications of Wire Rope Lanyards

Wire rope lanyards provide stable support and guarantee the safety of people and equipment in various industries and activities. In addition, they are a great option for many applications since they are adaptable, flexible, and strong. Due to their strength, longevity, and flexibility, wire rope lanyards are adaptable and frequently utilized in various industries. Examples of typical applications include:

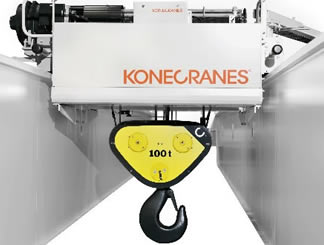

Engineering and Construction: Wire rope lanyards are frequently used in engineering and construction projects because they offer safe support for personnel and tools. They are employed in crane operations, suspended platform setups, and scaffolding systems.

Wire rope lanyards are another safety harness used to secure personnel in high-risk areas, including towers, bridges, and elevated platforms. They prevent falls and ensure workers' safety by offering a safe link between them and a fixed point.

Industrial Lifting Applications: Wire rope lanyards are also used in Industrial lifting applications to safely support big loads, including machinery, containers, and raw materials.

Applications in the Marine and Nautical Sector: Wire rope lanyards are utilized in various marine applications, including mooring operations, anchoring systems, and fastening boats and ships. Additionally, they are employed in maritime pursuits like offshore drilling and deep-sea diving.

Aerial Adventure Activities: Zip-lining, rock climbing, and canopy tours use wire rope lanyards. Participants can enjoy these thrilling activities with lanyards’ safe support.

Choosing the Right Wire Rope Lanyards Supplier

To make sure you have the most positive outcome when purchasing Wire Rope Lanyards from a Wire Rope Lanyards Supplier, it is important to compare at least 6 Manufacturers using our Wire Rope Lanyards directory. Each Wire Rope Lanyards Supplier has a business profile page that highlights their areas of experience and capabilities and a contact form to directly communicate with the manufacturer for more information or request a quote. Review each Wire Rope Lanyards company website using our patented website previewer to get an idea of what each business specializes in, and then use our simple RFQ form to contact multiple Wire Rope Lanyards businesses with the same quote.

Cranes

Cranes Electric Hoists

Electric Hoists Forklifts

Forklifts Hydraulic Lifts

Hydraulic Lifts Rope

Rope Wire Rope

Wire Rope Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services